FY01 MCON Project P-491

Project Description

As part of the Navy's long-term plan to transform Ford Island into a hub for commercial, residential, and operational support functions within Pearl Harbor, upgrading the island's aging infrastructure was essential. FY01 MCON Project P-491 — Sewage Force Main, Ford Island to Pearl Harbor Naval Shipyard - was the first of several critical infrastructure projects designed to support this redevelopment effort. The project consisted of constructing a new sewage force main and upgrading an existing pump station to accommodate increased wastewater demands associated with future development.

The newly constructed force main now serves as the primary conduit for wastewater from Ford Island, while the existing main remains available as a backup to ensure system reliability during maintenance or emergencies. To minimize environmental impact and operational disruption, the majority of the new force main was installed using horizontal directional drilling (HDD) — a trenchless technology that enables the pipeline to be placed along a pre-defined alignment with precision.

HDD was chosen specifically for the crossing beneath the Pearl Harbor Main Channel to avoid interfering with naval operations and to prevent the disturbance of potentially contaminated bottom sediments. On the Ford Island side, HDD also allowed for installation without affecting historically significant areas linked to the December 7, 1941 attack. Additionally, it enabled efficient navigation through the densely built shipyard area, which posed numerous utility and structural challenges.

Background

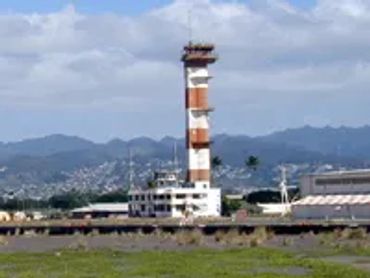

The completion of Admiral Clarey Bridge in 1998 marked a turning point for Ford Island, making it easily accessible and opening the door for future development. That same year, the USS Missouri — a decommissioned battleship — was permanently moored at Ford Island and opened to the public as a memorial and museum, honoring those who served in World War II. These milestones were part of the Navy's broader vision to transform Ford Island into a dynamic hub for operations, housing, and visitor attractions within Pearl Harbor.

To support this vision and accommodate the growing demand on utilities, the Navy launched several critical infrastructure upgrades. The first among them was FY01 MCON Project P-491, which involved the installation of more than 6,000 feet of 20-inch diameter high density polyethylene (HDPE) pipe to establish a reliable and redundant wastewater transmission system. The project also included comprehensive upgrades to the island's primary wastewater pump station, equipping it with high-capacity pumps to meet future flow requirements.

Contribution to the Well-Being of People and Communities

This project significantly improves wastewater transmission from Ford Island, enhancing both capacity and system reliability. These upgrades enable the Navy to move forward with the Ford Island Development Plan, which includes the construction of essential housing for Navy personnel, fosters economic revitalization in the region, and offers a platform to honor and highlight the historic importance of Pearl Harbor and its enduring role in the U.S. military heritage.

Resourcefulness in Planning and Solving Design Challenges

One of the most complex challenges faced in this project was installing the pipeline beneath the 1,200-foot-wide, 50-foot-deep Main Channel of Pearl Harbor. It was critical to avoid disrupting Navy ship movements — essential to national defense - and to minimize interference with harbor operations. Additionally, there were environmental concerns: disturbing the channel floor could degrade water quality and potentially release contaminants from historically industrial sediments, affecting marine ecosystems and nearby recreational areas.

A second major concern was the preservation of historically significant features on Ford Island, including WWII-era buildings and landmarks from the December 7, 1941 attack.

To overcome these challenges, the design team collaborated closely with the Navy to assess alternatives. Considerations included minimizing environmental impact, maintaining visual aesthetics, ensuring reliability, and preserving the site's historical integrity. The selected approach involved horizontal directional drilling (HDD), where an 8-inch pilot hole was drilled 30 feet beneath the channel bottom — eliminating the need for surface disturbance. This pilot hole was then enlarged to accommodate a 20-inch HDPE pipe, which was successfully pulled from Ford Island to the Shipyard. HDD also allowed the team to preserve the historic waterfront.

The HDD process presented its own difficulties: the length of the pull was unprecedented and tracking the drill head 80 feet underwater was complicated by the need to keep the channel clear of large vessels or barges. Instead, divers installed a tracking grid system on the seafloor to monitor drill head positioning and depth.

Another key challenge was crossing beneath the transport system used by the Shipyard's 500-ton cranes. Because these cranes are critical to operations, downtime had to be minimized. When discrepancies in foundation locations were found, the Navy, designers, and contractor worked together to quickly develop a new solution.

Maintaining uninterrupted wastewater service during construction was also a priority. An innovative bypass system was developed using a combination of high-capacity, low-head pumps to collect sewage and high-head pumps to transfer the flow into the existing force main — ensuring continuous service throughout construction.

Pioneering in Use of Materials and Methods

This project marked a significant advancement in applying horizontal directional drilling (HDD) with high-density polyethylene (HDPE) pipe. The use of the HDPE pipe provided several key benefits:

- Corrosion Resistance: HDPE is inherently resistant to both wastewater and seawater, ensuring long-term durability and minimal maintenance.

- Flexibility and Efficiency: The pipe's flexibility allowed it to bend around subsurface obstacles, reducing the need for costly fittings or additional structures.

- Minimal Disruption: HDD enabled installation with little to no interference with harbor activities or land-based operations.

- First of Its Kind: This was the first application of HDD for a submarine pipeline crossing at Pearl Harbor.

- Record-Breaking Installation: The Main Channel crossing set a new benchmark, becoming the longest single-pull HDD installation using HDPE pipe at the time.

Innovations in Construction

Installing large-diameter, heavy-walled HDPE pipe via horizontal directional drilling (HDD) required several forward-thinking construction techniques:

- Collaborative Monitoring: Because HDD for HDPE pipe of this size was still an emerging practice, the design team worked closely with the drilling contractor to monitor pulling forces throughout installation. This collaboration ensured that tensile stress levels remained within safe limits to prevent damage to the pipe.

- Precision Placement: Achieving accurate alignment was critical, especially given the proximity of historic bomb craters on Ford Island — some just 30 feet from the planned exit point. To ensure pinpoint accuracy, a wire grid tracking system was installed on the sea floor. This allowed the drill head's position and depth to be continuously monitored, resulting in a borehole exit within centimeters of the target location.

Impact on the Physical Environment

The use of horizontal directional drilling (HDD) significantly reduced the projects environmental footprint:

- Contaminated sediments beneath Pearl Harbor remained undisturbed.

- Dewatering operations and related issues were avoided entirely.

- Minimal handling and disposal of potentially contaminated groundwater and excavated soil was required.

- Construction-related disruptions were substantially lower compared to traditional open-cut trenching methods.

- The alignment successfully avoided impacts to numerous historically significant features along the route.

Beneficial Effects of the Project, Including Aesthetic Value

The project delivered multiple lasting benefits.

- It greatly improved the reliability and capacity of the wastewater system serving Ford Island.

- The enhancements support the Navy's broader revitalization efforts, enabling future development of Ford Island into a vibrant operational, residential, and cultural destination within Pearl Harbor.

Fukunaga & Associates, Inc

1357 Kapi'olani Boulevard, Suite 1530

Honolulu, Hawai'i 96814

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.